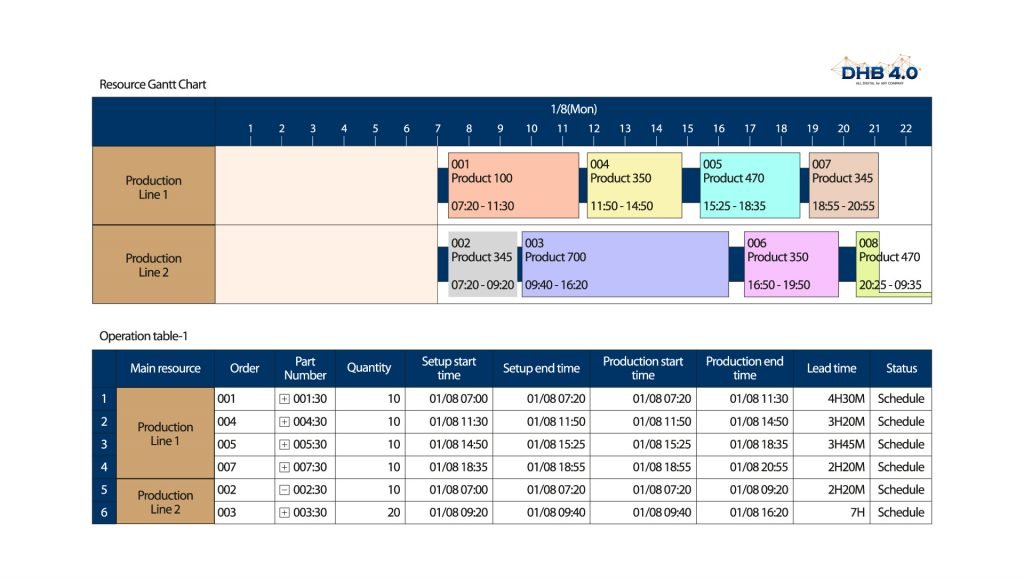

Only inside DHB4.0 you can have advanced planning & scheduling with powerful features that allow us to build a custom solution. It’s a solution designed to aid you in long and mid-term planning. Is an interactive, multi-constraint scheduling system that provides support for decision-making for overtime, order prioritization, production batches, due date negotiation, order processing. It enables manufacturers to respond quickly and intelligently to unexpected changes, while satisfying customer demands with shorter lead times. With our solution, you can perform risk analysis in real-time and also taking into account the system variation, which allows performing a probabilistic analysis to estimate the underlying risks associated with the schedule. The risk output generated will include the probability of meeting your goals defined in the experimenter tool considering scenarios expected, pessimistic, and optimistic.

Our tailored made production scheduling extends traditional APS to fully take into account the variation that is present in any production system, and provides the necessary output to the professionals in charge of that task in the companies, and also allows you to mitigate the risk and uncertainty. It’s totally integrated with all of our solutions, especially the FlexSim Live, which allows users to model any system at any level of detail and can incorporate all of the random variations.

Only inside DHB4.0 you can have advanced planning & scheduling with powerful features that allow us to build a custom solution. It’s a solution designed to aid you in long and mid-term planning. Is an interactive, multi-constraint scheduling system that provides support for decision-making for overtime, order prioritization, production batches, due date negotiation, order processing. It enables manufacturers to respond quickly and intelligently to unexpected changes, while satisfying customer demands with shorter lead times. With our solution, you can perform risk analysis in real-time and also taking into account the system variation, which allows performing a probabilistic analysis to estimate the underlying risks associated with the schedule. The risk output generated will include the probability of meeting your goals defined in the experimenter tool considering scenarios expected, pessimistic, and optimistic.

Our tailored made production scheduling extends traditional APS to fully take into account the variation that is present in any production system, and provides the necessary output to the professionals in charge of that task in the companies, and also allows you to mitigate the risk and uncertainty. It’s totally integrated with all of our solutions, especially the FlexSim Live, which allows users to model any system at any level of detail and can incorporate all of the random variations.

North America: +1 (645) 221.6090

Europe: +351 (920) 799.717

LATAM: +55 (19) 9 8251.9536