The Oil industry is one of the pioneers in the widespread adoption of optimization techniques. Improve and increase digitalization with responsiveness and best decision-making inside all fields of the oil & gas market for sure is a tough process. Imagine a digital hub specifically developed with refinery-wide scheduling that simultaneously schedules all key activities from within a robust digital platform to increase production throughput.

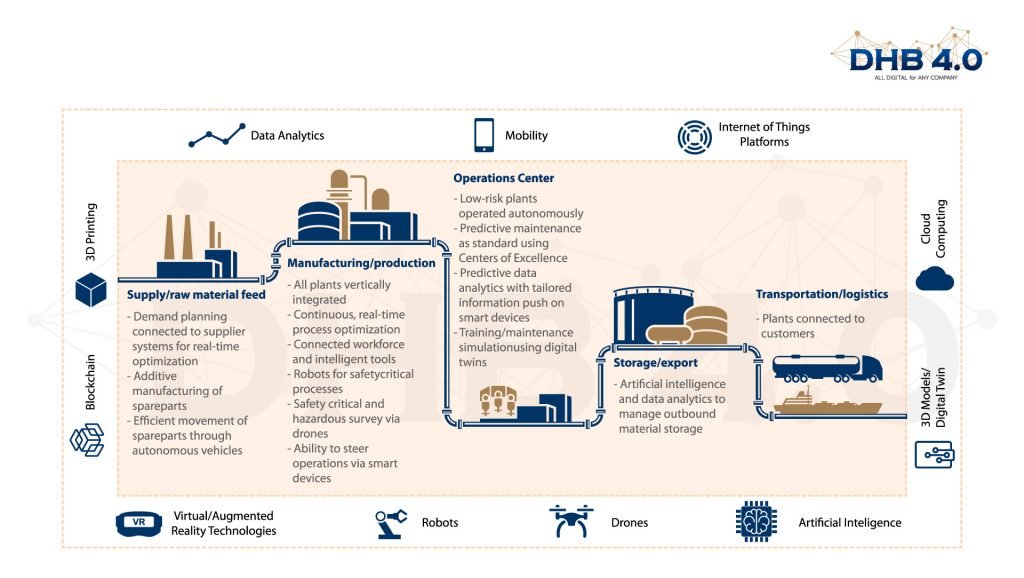

DHB4.0 is a solution totally different from the common planning & scheduling solutions available in the oil & gas market. It´s more complete than the conventional solutions and it incorporates many digital and modern solution in a digital hub like AI, VR, AR, and others.

VISUALIZE THE COMPLET PRODUCTION AND SCHEDULE

You will be able to full vision and comprehensive oil & gas system activities, plus a refinery-wide view of the production schedule while you can simultaneously planning & scheduling all key refinery activities in a digital platform and also plan your future in a virtual environment.

TAKE YOUR OPERATION TO THE MAXIMUM

Increase your oil & gas systems capacity and take it to maximize productivity through a robust digital schedule solution. Configure your schedule to match the true operational constraints.

TAKE YOUR PLANNING TO AN EFFICIENTLY AND A CLOUD MULTI-USER ENVIRONMENT

All company levels, from C-level to the operations with a flexible and multi-user environment, can have all information in your hands in real-time.

The full solution enables schedulers to work simultaneously on the same schedule with automated alerts to changes or even run a new optimized scenario that takes to higher productivity.

APPs, ANALYTICS & SERVICES

Improve operations to new levels of efficiency, asset performance, and people productivity. DHB 4.0 and its development team combine to create a leading engineering and industrial software company.

EDGE CONTROL

Real-time solutions for control at the edge of the network because not all control decisions can be made remotely. DHB4.0 is the right solution for real-time controls and planning decisions. With your fully designed framework develop for each specific business.

CONNECTED PRODUCTS

Smart devices with embedded communication transmit process and equipment data for improved field operations, all being organized and structured within a robust BigData solution.

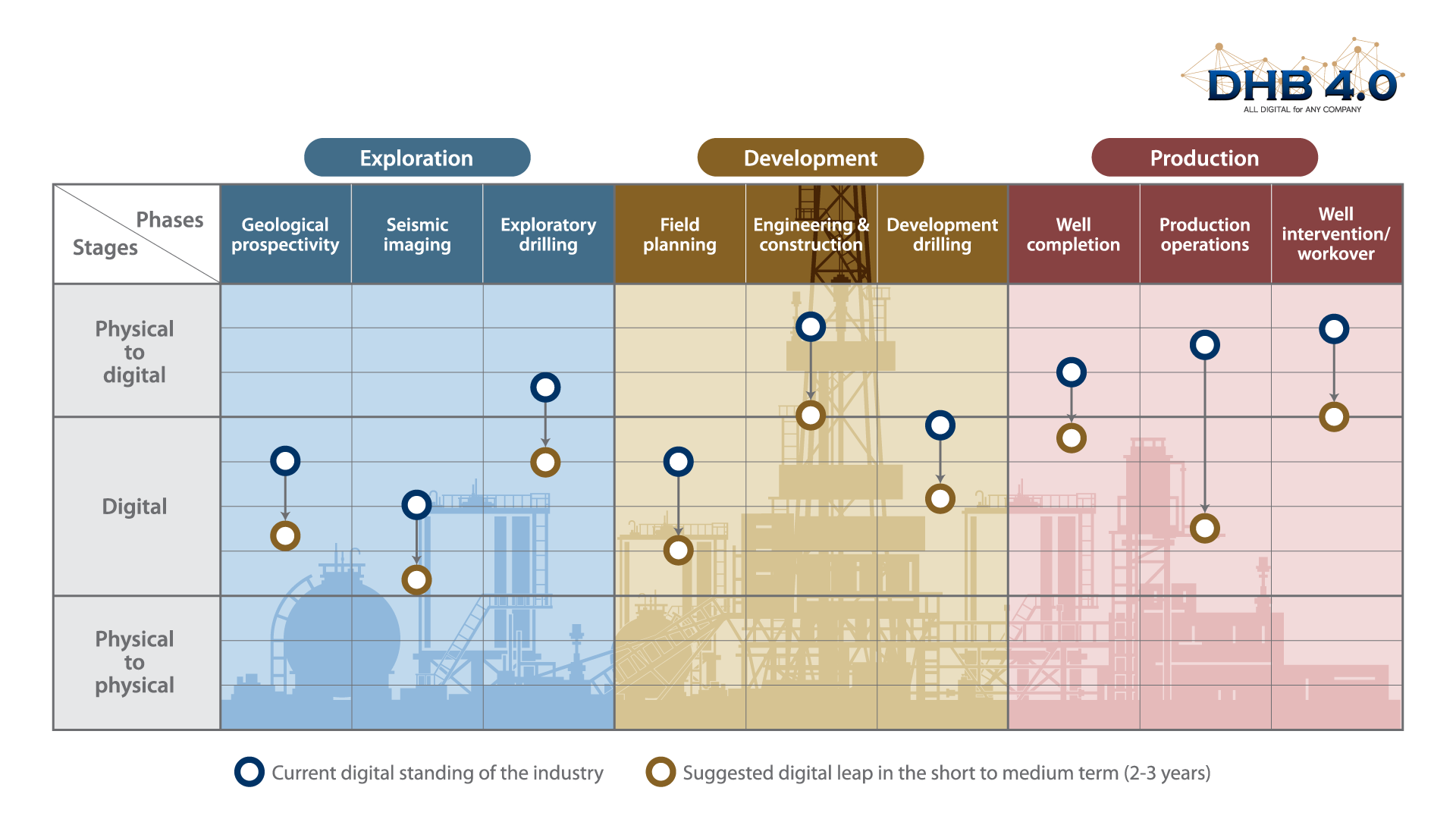

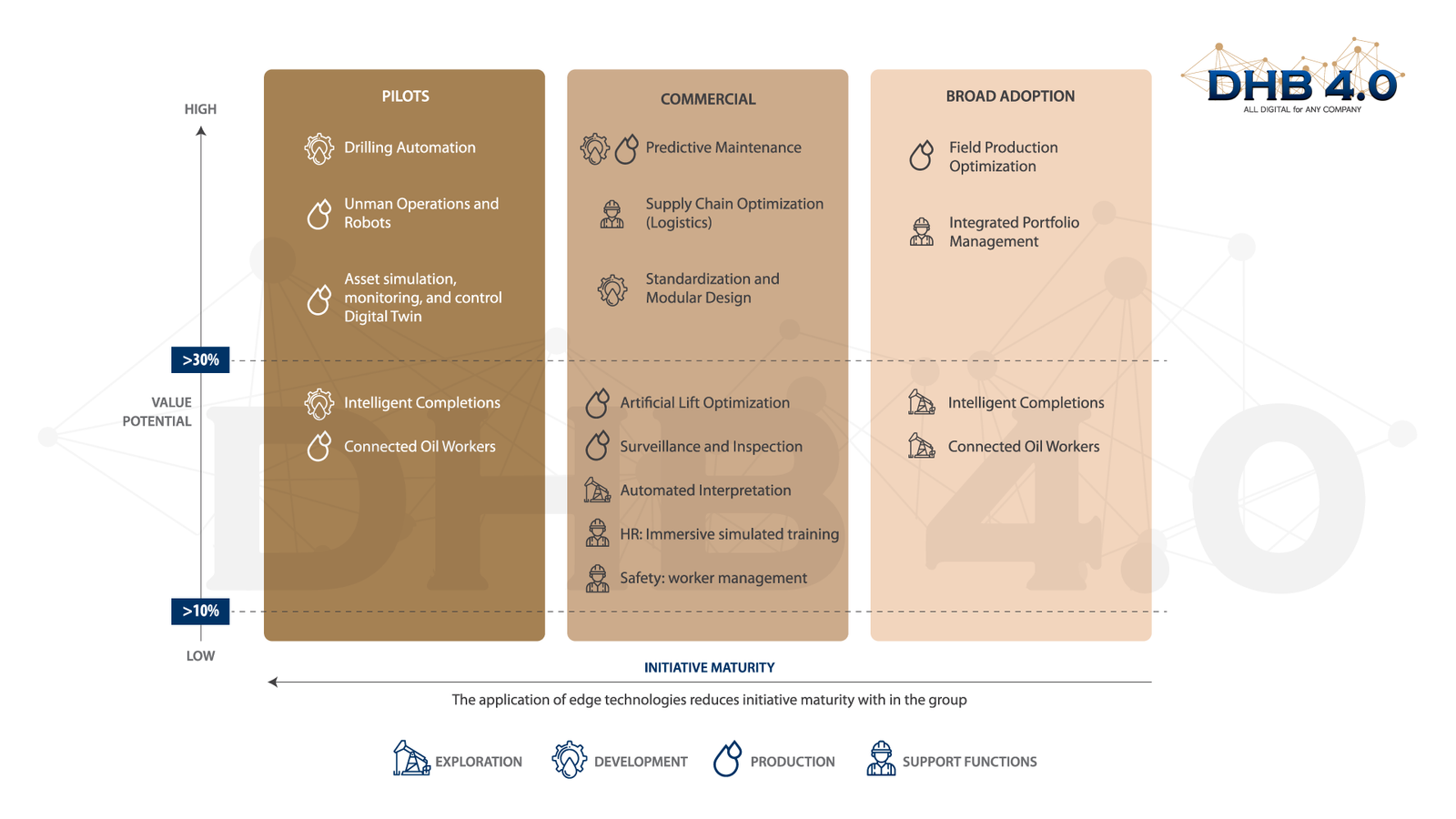

DHB4.0 can work in the oil & gas field per instance for a full digitalization process and used to automatically schedule day-to-day operations. Also, you can create plans to be compared on Value at Risk and timeliness of orders when we are talking about generating different plans via optimization. Even for refinery optimization processes and digitalization, the applications are wide. The term “Refinery optimization” has consequently evolved to become a multi-faceted concept. At an abstract level, refinery optimization is about getting the most from the existing assets; by extension, it can also refer to the most profitable investments in new equipment or new assets. This first distinction gives rise to 2 horizons of application to refinery optimization: long-term, structural optimization, and short-term operations optimization.

Moreover, operations management itself can be addressed in a variety of ways, depending on whether the approach taken to refinery optimization is bottom-up, or top-down:

The top-down approach is based on hierarchical optimization: the refinery optimization problem is addressed as a succession of optimization problems of different time magnitudes and granularities. The first problem is a mid-term planning problem and is concerned with the refinery as a whole- and a time frame of one to several months. Subsequently, the time frame is subdivided into finer time intervals. At the lowest level, the theoretical goal is to achieve operations scheduling on a day to day basis

The bottom-up approach is one that starts with local problems and tries to aggregate them into a consistent solution at the refinery level

Moreover, operations management itself can be addressed in a variety of ways, depending on whether the approach taken to refinery optimization is bottom-up, or top-down.

In contrast to traditional bottom-up approaches – which attempt to build an overall solution by aggregating local solutions – we start by achieving a feasible, “good quality” overall solution using our smart simulation engine. Then, guided by the consistent overall solution, we seek to optimize local operational challenges.

Our innovative approach to refinery optimization takes account of 2 crucial facts:

- Day-to-day operations are subject to uncertainty,

- Regardless of the inherent formal difficulty of achieving an overall refinery schedule optimization, and overall optimized schedule is of little use.

This is simply because an overall solution achieved that way is inherently unstable: the slightest change or unforeseen event means that the whole schedule must be rebuilt. And given the huge amount of inertia in such a large system, any sudden change of trajectory consumes an equally huge amount of energy.

Under this pragmatic perspective, refinery optimization appears as the search for a maintainable globally feasible, locally optimized schedule. Optimization is applied to sub-systems where a high economic impact is achievable.