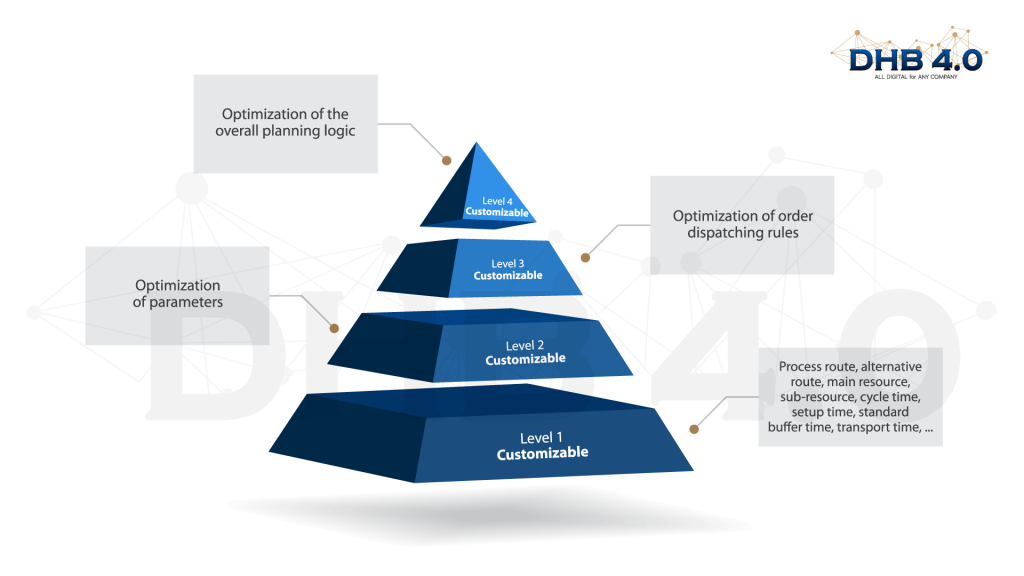

Within our solution for digital transformation DHB4.0, it is possible to create mathematical equations to solve problems in order to find the best possible solution among all viable solutions. It means finding a solution that maximizes or minimizes something, according to one´s purposes.

We deal with complex problems, with a very large number of variables, therefore, defining values and making decisions for all of them can become extremely costly and difficult, considering that one decision can impact on others. Not to mention that these decisions still have to comply with numerous restrictions.

However, normally we do not just want to find a solution. The competitive context in which many companies are makes it imperative that the decisions made are not only feasible but also very good. And why not great? Why not look for the solution that will bring the greatest profit? Or the lowest cost? Better decisions can be adopted when using mathematical optimization.

And how can it be done? The existing problem must be mapped, with its variables, parameters, constraints, and objectively defined. A mathematical model or a mathematical formulation is then created: a set of equations that will represent this problem. Some simplifications may be necessary, and it is at this point that the expert who is developing the models comes in. Finally, the best resolution approach is chosen or created.

Thus, mathematical optimization can become a great aid tool. It is not about replacing those who make the decisions but allowing them to have in their hands something that can further leverage what is being decided. It is about giving the decision-makers a greater input so that their time and experiences can be used in the most efficient way possible. Our development is carried out using current and modern solutions, such as the issue of data analysis with machine learning techniques that can help to define optimization variables

Better product allocation in plants, seeking greater capacity utilization, and reducing the total cost of the system. Increase in work efficiency through a lean distribution of resources and employees.

Optimization of the transport fleet usage by defining better routes according to distances, capacities, and costs. Analysis and sizing of the fleet according to the customers´ demand. Greenfield field analysis, greenfield analysis with roads, and brownfield analysis are some examples that can be used in further supply chain network optimization.

Integration of the value chain to achieve a single global aim. Optimization of the balance among quality, cost, and productivity. Optimal selection of raw materials determining the operational point that minimizes production cost or maximizes profit.

Reduction of storage and transportation costs by determining where and when to produce. Optimal inventory determination to avoid breaks without blowing the cost. Supply Chain network optimization where we want to find an optimal combination of factories and distribution centers with the lowest costs.

Align production with the demand through better planning operations and inventory control. Achieve lower costs and increase yield by optimizing production planning and/or sequencing, or the arrival of ships with raw materials and products.

Definition of the best locations for your plants and distribution centers, taking into account your supply capacities, costs and customer demands.

Research and Audit

The procedures put in place when starting a business quickly become obsolete due to the rapidly changing market trends. As such, it is paramount that these processes are streamlined to maintain relevance in the market.

Pain Point Identification

Achieving higher returns on investment ensures that you have peace of mind and get your entire team to focus on other issues within the enterprise. Our team comes on board to offer you a high-quality service that would give you and your team this kind of peace.

Solution Implementing

Having a team of professionals with a track record of proven successes in what they do is more than enough guarantee of peace of mind.

Our process optimization consulting services ensures that in the long run, you end up saving more and getting value for your money from the professional services we guarantee.

Result Maintenance and Analyses

Process optimization consulting is also significant as far as saving resources and finances are concerned. From the outlook, outsourcing services for any corporation may seem to be an extra cost to the business. However, for these specific services, it would be more expensive to have an entire unit that handles it. This is the primary benefit of hiring a consulting company.

Process Optimization – Key Factors

A key aspect of any transition from an old system is the training of those who will be tasked with using the new technology.

Flexsim Professionals will work with you to optimize your business processes so that information flows better in the future.

At FlexSim Brasil we have integrated, efficient, and flexible improvement processes. We are capable to optimize the utilization of business resources.

You will receive practical methods of moderation, the documentation of processes for all equipment manufacturers using appropriate IT tools.

Our process optimization services reduce delays and enhance your satisfaction in business results, encourage collaboration with partners and customers.

North America: +1 (645) 221.6090

Europe: +351 (920) 799.717

LATAM: +55 (19) 9 8251.9536