The mining industry is embracing the opportunities of digital transformation and facing up to its challenges.

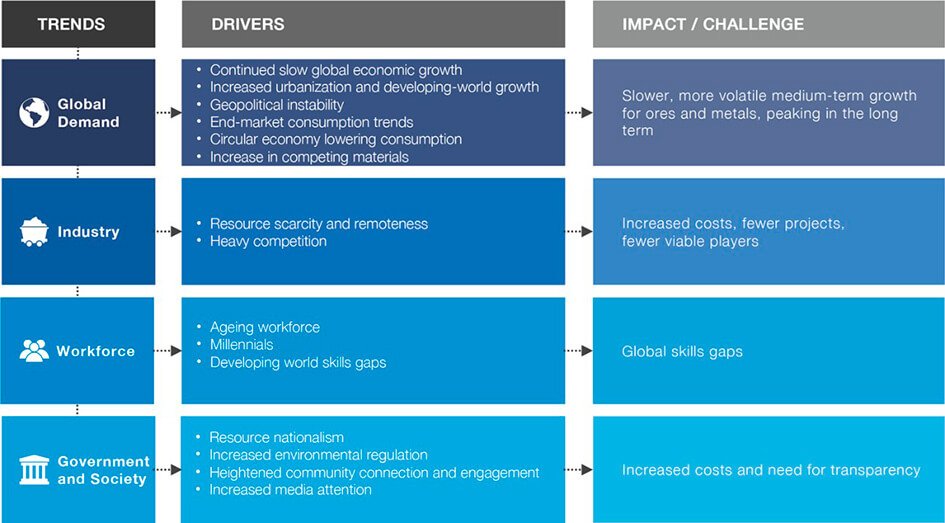

Fiven years after this cenntury’s commodity boom peaked in 2011, the global Mining and Metals industry is still adjusting to a set of strong headwinds. These include anaemic global demand growth as China’s economy shifts away from resource-intensive manufacturing; massive excess capacity, weak pricing and increasing volatility; workforce skills gaps; increasing pressure from customer requirements; growing resource nationalism and regulation; declining resource access and quality; and mounting trade friction along with all steps in the value chain.

Source: World Economic Forum

There is no evidence to suggest that these trends will reverse any time soon. On the contrary, they are likely to persist indefinitely, defining the industry’s ‘new normal. Moreover, across industries, the current value chain structure with incumbent businesses is being challenged not only by macroeconomic conditions but by increasingly fast-moving and pervasive digitalization.

These digital technologies have tremendous potential to move beyond stagnant growth and deliver exceptional shareholder, customer and environmental value. In particular, there are four themes that are expected to be central to the digitalization of the industry over the next decade

Deploying digitally-enabled hardware tools to perform or improve activities that have traditionally been carried out manually or with human-controlled machinery. Key initiatives in scope are sensors, robots and 3D printing.

Using connected mobility, and virtual and augmented reality to empower field, remote and centralized workers in real-time. Key initiatives in scope are connected workers and remote operating centres.

Linking operations, IT layers and devices or systems that are currently separate. Key initiatives in scope are information technology (IT) and operational technology (OT) integration, asset cybersecurity and integrated sourcing, data exchange and commerce.

Leveraging algorithms and artificial intelligence to process data from sources within and beyond the traditional value chain to provide real -time decision support and future projections. Key initiatives in scope are advanced analytics, simulation modelling and artificial intelligence.

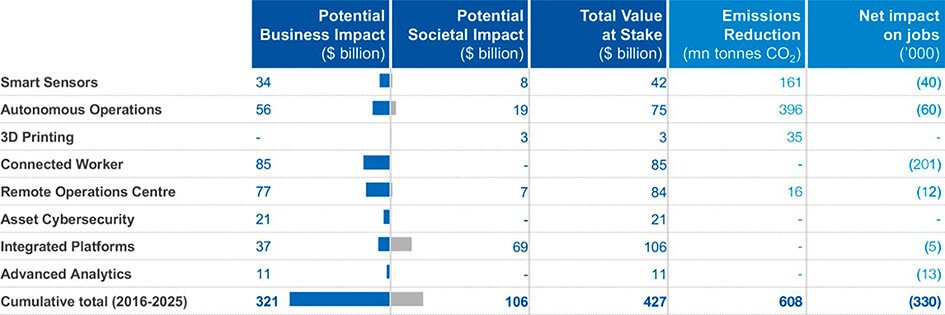

Our value-at-stake analysis is a quantitative model that aims to assess the cumulative value impact over the next 10 years of digital transformation initiatives on the Mining and Metals industry, its customers, society and the environment. Key findings from this analysis show that digitalization could generate:

However, the potential loss of about 330,000 jobs, or nearly 5% of the workforce, over the next decade as a consequence of increased digitalization must also be considered and, where possible, mitigated.

Mining and Metals: value at stake for industry and society (2016-2025, by digital initiative)

Source: World Economic Forum

There is no evidence to suggest that these trends will reverse any time soon. On the contrary, they are likely to persist indefinitely, defining the industry’s ‘new normal. Moreover, across industries, the current value chain structure with incumbent businesses is being challenged not only by macroeconomic conditions but by increasingly fast-moving and pervasive digitalization.

These digital technologies have tremendous potential to move beyond stagnant growth and deliver exceptional shareholder, customer and environmental value. In particular, there are four themes that are expected to be central to the digitalization of the industry over the next decade

Deploying digitally-enabled hardware tools to perform or improve activities that have traditionally been carried out manually or with human-controlled machinery. Key initiatives in scope are sensors, robots and 3D printing.

Using connected mobility, and virtual and augmented reality to empower field, remote and centralized workers in real-time. Key initiatives in scope are connected workers and remote operating centres.

Linking operations, IT layers and devices or systems that are currently separate. Key initiatives in scope are information technology (IT) and operational technology (OT) integration, asset cybersecurity and integrated sourcing, data exchange and commerce.

Leveraging algorithms and artificial intelligence to process data from sources within and beyond the traditional value chain to provide real -time decision support and future projections. Key initiatives in scope are advanced analytics, simulation modelling and artificial intelligence.

Source: World Economic Forum

Connectedmworker technologies have numerous applications in the industry. For instance, equipping workers with connected, intelligent wearables and mobile devices allow mine and plant management to capture critical information in real-time. This also enables seamless communication; immediate, remote expert assistance, diagnosis and real-time guidance; and ‘follow-complete-document’ workflows that can be carried out directly in the field. Through better tracking of individuals, especially in dangerous events, it is estimated that around 500 lives could be saved and more than 20,000 injuries prevented during the next decade.

Advances in digital technology could transform Mining and Metals as an industry and at the enterprise level. Though the digital technologies and capabilities discussed are in varying stages of maturity and usefulness, one can already see a vast difference across Mining and Metals companies in terms of testing, adoption and expected benefits. For those organizations that can move from being digital laggards to digital-first movers, the value is real; a pro forma projection of value at stake at the enterprise level for an average Mining and Metals company showed a substantial increase in 2025 EBITDA of a digital first-mover versus a digital laggard.¹ Companies – in collaboration with the larger community – must take steps to enhance their digital capabilities, helping them improve their bottom line, become more responsive and resilient to industry challenges, and develop into more sustainable, transparent organizations.

Successful digitalization will require collaboration between industry leaders, communities and policy-makers. The following is a set of considerations developed for both industry and other stakeholders.

For industry

For communities, policy-makers and governments

North America: +1 (645) 221.6090

Europe: +351 (920) 799.717

LATAM: +55 (19) 9 8251.9536